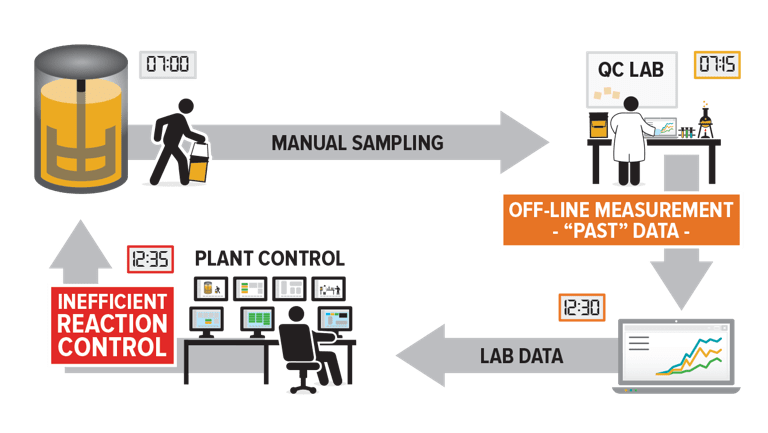

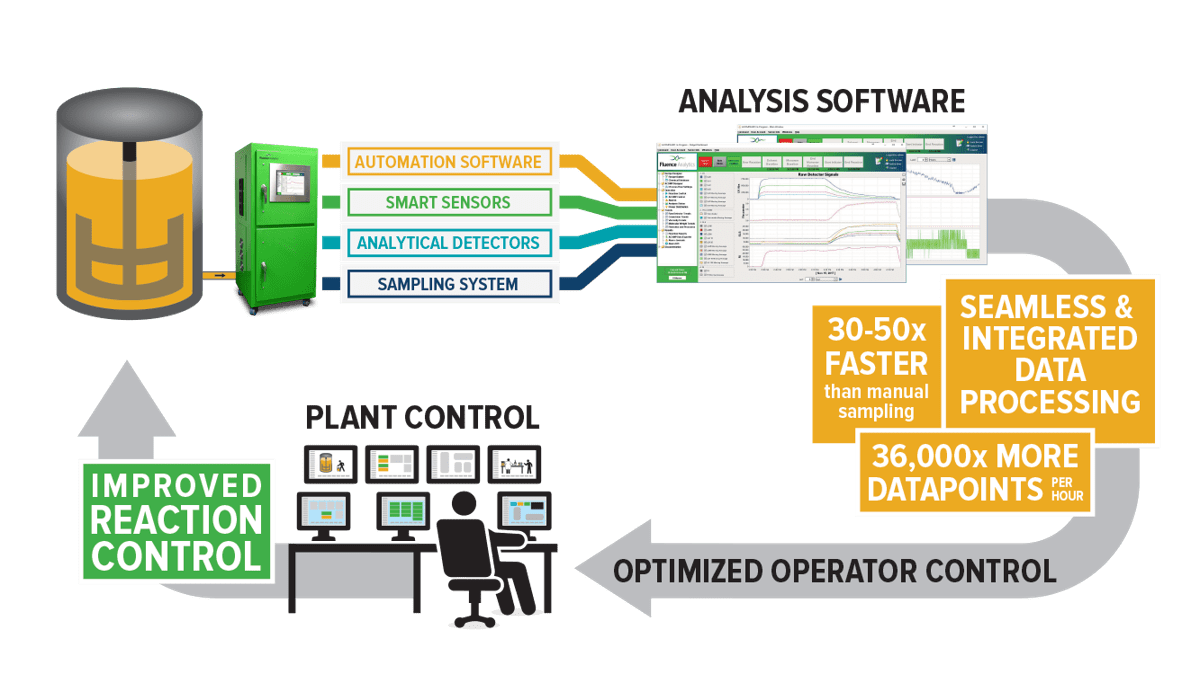

Industry trends show that manual sampling is the standard method of measurement during the manufacturing of water soluble polymers. Yokogawa Fluence Analytics is shifting the industry paradigm with ACOMP, a smart manufacturing system that generates real-time measurements of critical properties during the production of water soluble polymers. Using these real-time insights, customers have reduced cycle times and off-spec batches while improving product quality. Furthermore, with enhanced data and control, customers can scale up faster and accelerate the next generation of products to market. Whether you are making water soluble polymers for construction, automotive, flocculation, medical or electronics applications, get ahead of your competition today with ACOMP.

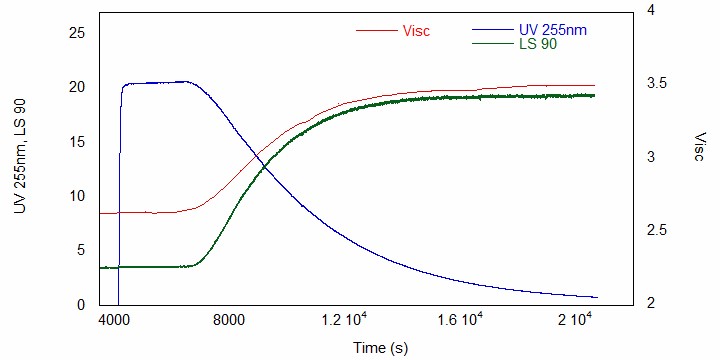

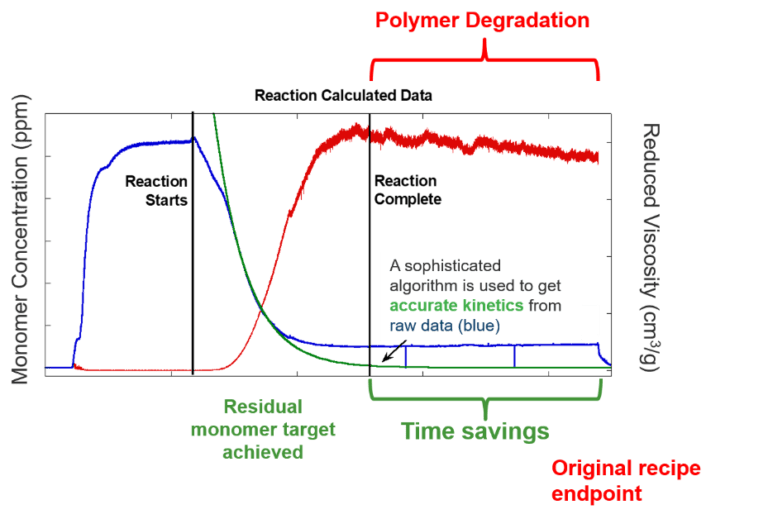

ACOMP continuously generates realtime analytics on polymer properties, including molecular weight, viscosity, composition, residual monomer and monomer conversion. ACOMP’s realtime polymer analyses have contributed to dynamic, optimized process control and reduced cycle times — decreasing overall costs for customers.

ACOMP has successfully monitored many water soluble polymer chemistries that are used in a variety of applications. These polymer families include polyacrylamide (PAM), polyDADMAC, polyamine, polyethyleneimine (PEI), quaternary ammonium compounds (QAC), Polyvinylpyrrolidone (PVP) and copolymers, polyvinyl methyl ether/maleic anhydride (PVM/MA), Polyvinyl alcohol (PVOH), Polyacrylic acid (PAA) and copolymers, and Polyethylene glycols (PEG).

Below is a link to an application note where ACOMP successfully monitored the polymerization of PVP under varying initiator concentrations.

“We are excited about the cycle time savings we are seeing with ACOMP, but particularly excited about how it can help us improve the quality of our polymers. We pride ourselves in distinguishing our offerings in the marketplace with unmatched service and quality. ACOMP has helped us advance that cause.”

Nalco, an Ecolab Company, partnered with Yokogawa Fluence Analytics to pioneer ACOMP in a facility manufacturing water soluble polymer. Nalco leveraged ACOMP’s realtime polymer analytics to reduce batch cycle times by 17% on an inverse emulsion polyacrylamide reactor. Two years later Nalco purchased a second ACOMP system for another reactor at the same facility.