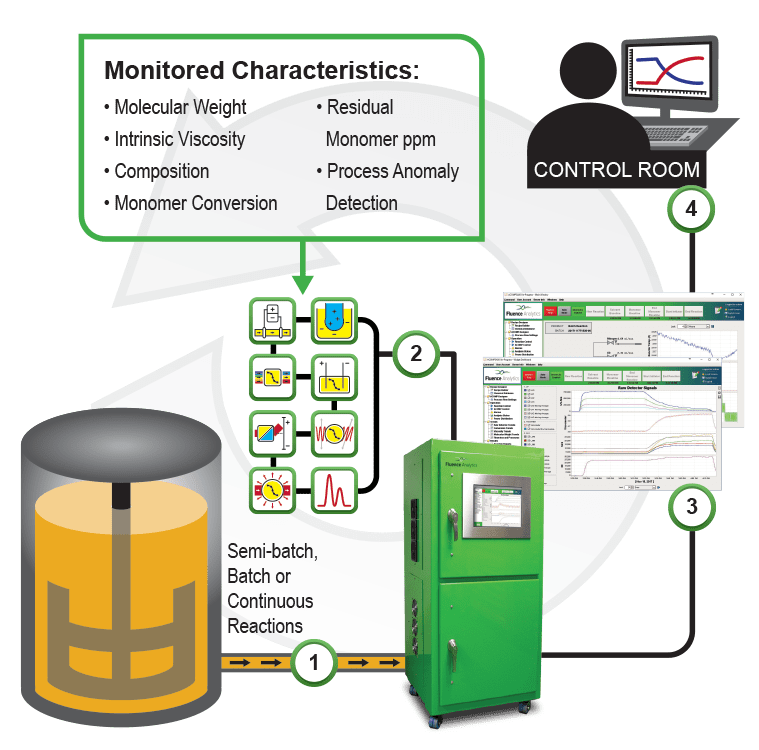

ACOMP is an automated smart manufacturing system that continuously analyzes polymers during production, yielding real-time data about reaction kinetics and polymer properties such as residual monomer, monomer conversion, polymer composition, molecular weight and intrinsic viscosity.

This automated monitoring solution allows for tighter process control, resulting in increased polymer yields, quality and consistency, increased worker safety, reduced cycle times, reduced VOCs, and reduced energy and raw material usage. Beyond allowing the user to monitor polymerizations in real-time, ACOMP enables the user an ability to control specific desired polymer characteristics.

During the fracking boom, there was high demand for a number of enhanced oil recovery chemicals, and many manufacturers sought ways to increase capacity with existing assets. Nalco, an Ecolab Company, innovatively partnered with Yokogawa Fluence Analytics to pioneer the use of ACOMP in one of its manufacturing facilities, subsequently leveraging the smart manufacturing system’s real-time data streams to reduce batch cycle times by 17%.

ACOMP has been applied to and demonstrated significant value in many polymerization applications, including elastomers, adhesives, paints and coatings, and many water-soluble polymers.

Polymer is continuously extracted from the reactor

⇓

Automated real-time measurements are made with multiple sensors

⇓

Proprietary analysis algorithms output key parameters for optimization

⇓

This enables:

Optimized process control, Plant digitization, Reduced cycle times, Improved yields and consistency

ACOMP is a smart manufacturing product that can help polymer manufacturers implement digital transformation projects. The system includes dozens of smart sensors and a detector train which enables real-time characterization of many polymerization processes. ACOMP detectors include Ultra-Violet/Visible Absorption (UV/Vis), Differential Refractometer (DRI), dilute solution single capillary viscometer (Visc), multi-angle light scattering (MALS), and others.