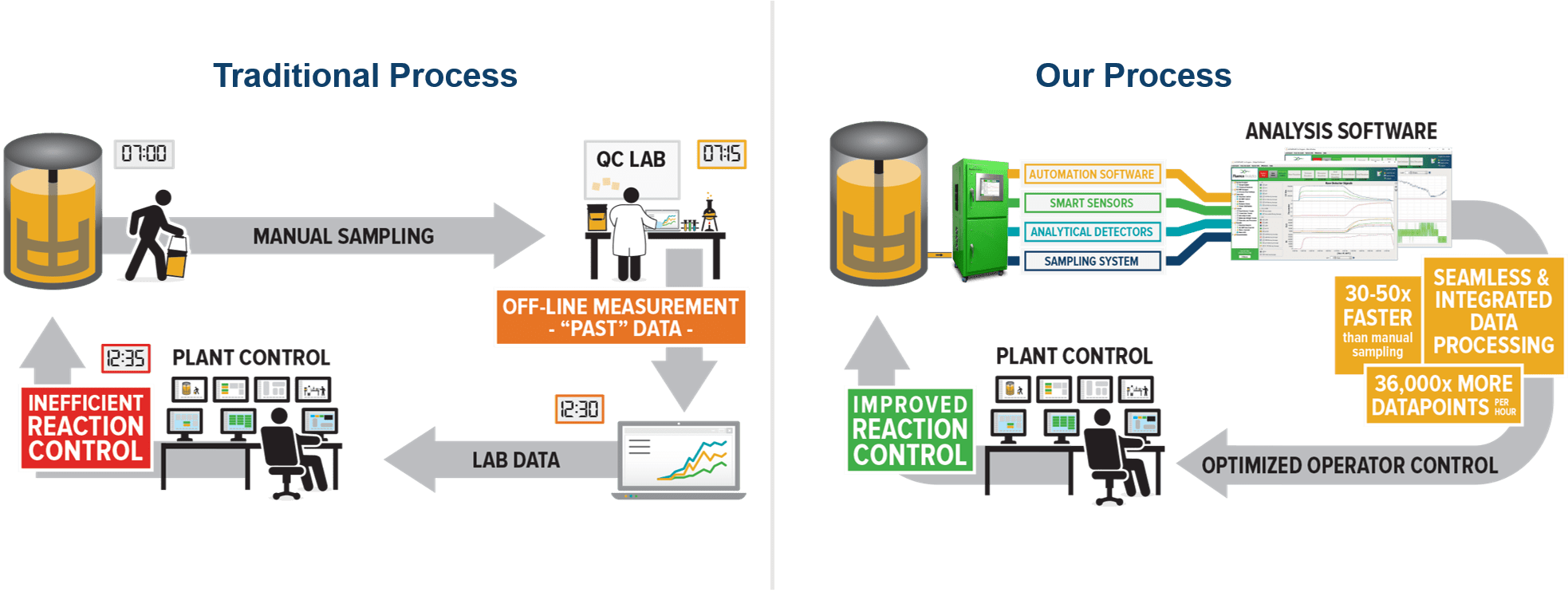

Historically, companies produce Ethylene Propylene Diene Monomer (EPDM) rubber without monitoring what happens inside the polymer reactor. Many manufacturers employ chromatography measurements once the reaction is complete or intermittently during production or R&D. Thus, there is a lack of realtime data which results in reactions running longer than required to mitigate against off-spec rubber polymer batches. Such a process consumes more energy, operator time and equipment availability than is required. Conversely, ACOMP, an innovative product available from Fluence Analytics, yields continuous, realtime measurements on critical polymer properties during the production and R&D of EPDM rubber.

By providing realtime insights, Fluence Analytics is disrupting the standard production processes for EPDM rubber. ACOMP continuously generates realtime data streams with molecular weight, viscosity, composition, residual monomer and monomer conversion measurements.

Abstract

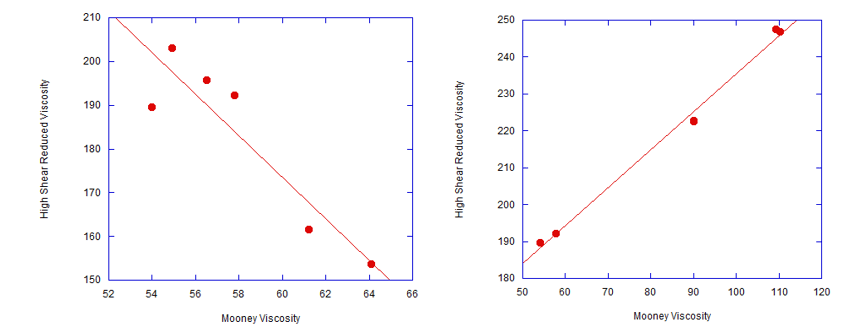

Automatic Continuous Online Monitoring of Polymerization reactions (ACOMP) was successfully used to measure the low and high shear reduced viscosity (RV) of Lion Elastomers’ ethylene propylene diene monomer rubber (EPDM rubber). The analyzed samples came from the production line and were quickly measured to simulate online measurement conditions as best as possible, i.e. hexane/cement elastomer mixture. ACOMP generated data that was used to build correlations between the RV and the compositional and physical properties of the EPDM rubber. The correlations showed a linear relationship between the RV measured by ACOMP and Mooney viscosity.

Furthermore, the correlations were unique by product grade. In addition, correlations between the RV and the EPDM’s percent composition of various monomers and other process chemicals were found. Because ACOMP can monitor RV and other values of an ongoing reaction in realtime, the potential for developing relevant correlations is an expected benefit of continuous data. Ultimately, ACOMP data can be used for both monitoring and enhancing the control of polymer manufacturing at the industrial scale, leading to improved production yields, efficiencies and minimum off-specification product. Additionally, Lab ACOMP can be used for the discovery and scale up of new products as they are developed.

Results

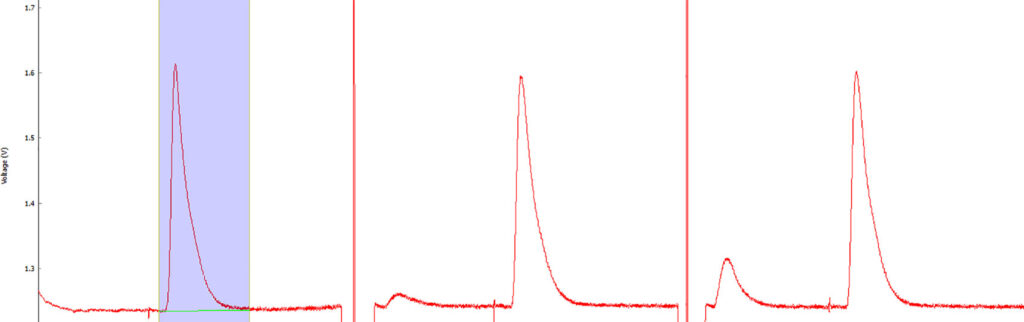

Figure 1 shows raw detector signals for the low shear viscometer for the three trials of one EPDM rubber sample. The solvent baseline is clearly seen before the sharp peak occurring when the EPDM sample hits the detector which is followed by a quick return to the baseline.

Comparison of this data, along with the high shear viscometer data to known compositional and physical properties, yields several valuable correlations. Figure 2 shows the correlation between reduced viscosity from ACOMP’s high shear viscometer and the Mooney viscosity for two different grades of EPDM rubber during the process of a grade changeover.

Conclusion:

The additional insight derived with the correlations of RV to the chemical composition recipes used in this study can likely be utilized to further optimize EPDM production to achieve a target Mooney viscosity. It is expected that correlations to lab data, utilizing a much larger process dataset, will be on a grade dependent basis, i.e. a range for RV or high shear RV will be developed to target specific end performance properties.

ACOMP has also successfully monitored other types of rubber. These include Styrene Butadiene Rubber (SBR), Solution Styrene Butadiene Rubber (SSBR), Emulsion Styrene Butadiene Rubber (ESBR), Styrene Isoprene Rubber (SIR), Acrylonitrile Butadiene Styrene (ABS), Nitrile Butadiene Rubber (NBR), Butyl Rubber, and Acrylonitrile Styrene Acrylate (ASA).